Every single ColorEdge monitor is calibrated and adjusted at the EIZO factory after assembly. This individual optimization of each device is the only way to achieve the precision that countless creative professionals around the world rely on every day.

EIZO Academy

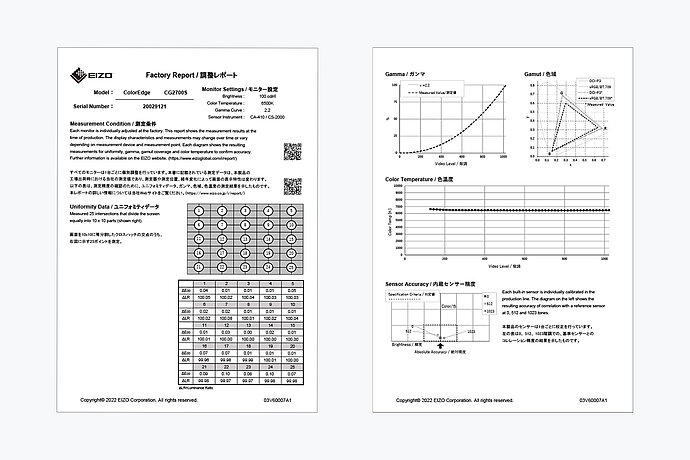

Calibration report

How to read the ColorEdge Factory Report about the factory calibration.

In order to prove the excellent precision of the EIZO factory calibration, all ColorEdge monitors of the CG series as well as models of the CS series, which have been launched on the market from 2023, are delivered with an individual calibration report (factory report). For CG series models, the report can also contain measured values for the precision of the built-in calibration sensor.

This calibration report proves the excellent precision of your monitor at the time of production and provides information on the individual measured values and the adjustment result.

Depending on the model, the scope of the calibration report may vary.

Let's take a look at what information you can read from the calibration report:

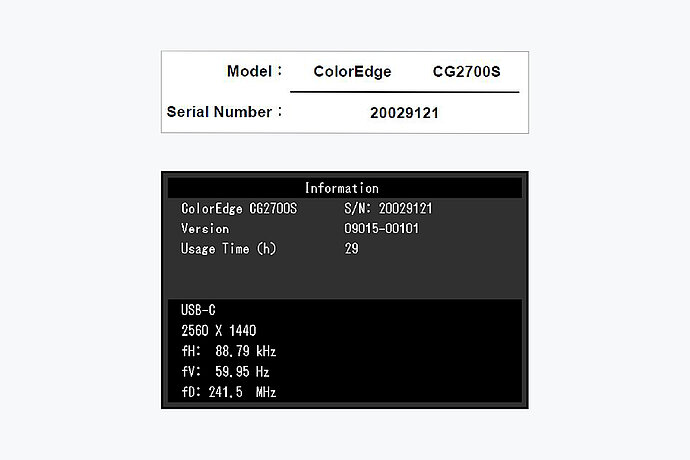

Model / serial number

At the top of the calibration report, you will find the product name and serial number (S/N) of your monitor. The serial number can also be found on the type plate on the back of your device and in the electronic monitor menu (OSD) under the "Information" menu item.

Monitor settings

The settings, measurement conditions and the measuring device used are listed here. The four points described in the report are:

- Brightness

- White point

- Gamma curve

- Measurement sensor used

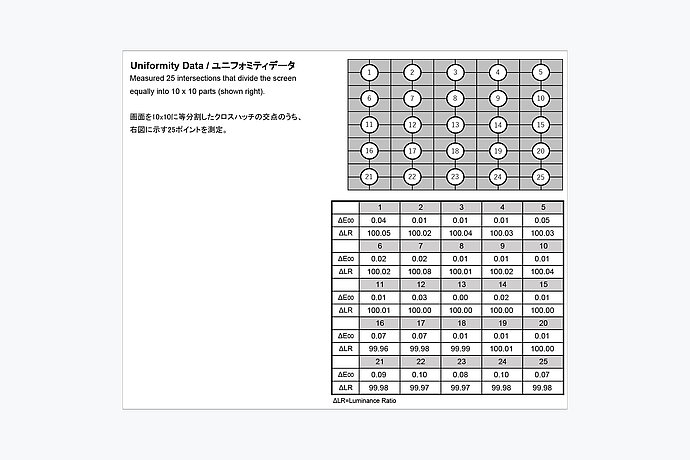

Homogeneity

Without correction, all LCD panels exhibit inhomogeneities due to their design. For most everyday applications, these are not disturbing, which is why they are not corrected in office monitors, for example. As a creative professional, however, you need to be able to rely on the image display of a monitor matching the image file exactly and being homogeneous and precise across the entire surface.

To ensure this precision, EIZO measures the display area of each ColorEdge monitor in 25 individual segments using a high-precision sensor optimized for this purpose. If deviations are detected that fall outside the strict EIZO limits, these are corrected.

The results table

In the results table you will find the values for color deviations (⊿E00) and brightness deviations (⊿LR ) of your monitor for all 25 measuring points. The reference value for these deviations is the middle measurement field (field 13).

Color deviation ⊿E00 (Delta E 00)

⊿E00 is a numerical value and expresses the color difference between the target and actual value. The larger the value, the more clearly the color deviation is visible to the human eye.

The table shows the color deviation of each point from the center point (field 13).

For the classification of these values: As a rule of thumb, it can be assumed that a ⊿E of 1-2 is not recognizable to the human eye, a ⊿E of 2-3 is usually only recognized by an extremely trained eye and a ⊿E of 3 or more is also noticeable to an untrained eye.

Brightness deviation ⊿LR (Delta LR)

⊿LR provides information about the homogeneity of the brightness (luminance) of the screen. The table describes the brightness ratio of the individual measurement points compared to the middle measurement field (field 13), which is set at 100% as the reference point.

DUE (Digital Uniformity Equalizer)

The patented Digital Uniformity Equalizer (DUE) corrects color and brightness drifts even after the monitor has left the EIZO factory. This is achieved by controlling the tonal values on a pixel basis.

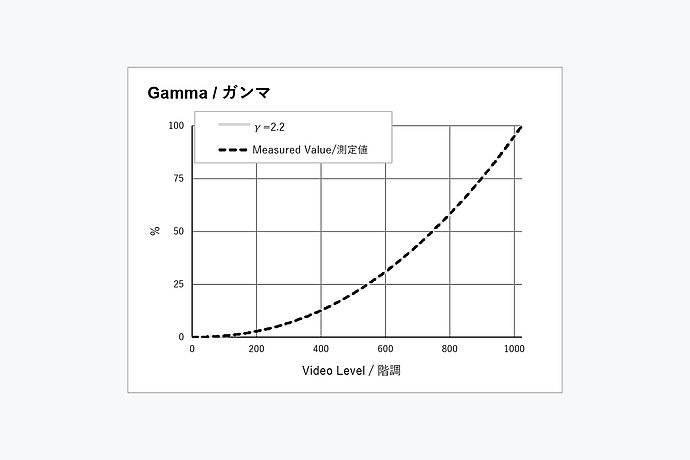

Gamma

With an LCD, the brightness gradient is not as precise as you need as a creative. This is why the brightness gradient is measured and adjusted in the corresponding brightness levels.

As human perception is not linear, this correction is based on the standard gamma curve of 2.2 that is most commonly used on both Windows and Mac computers. This gamma correction ensures that the brightness curve is set correctly and is also based on human perception so that the brightness curve looks linear to the viewer.

As part of the factory calibration, the course of the gamma curves is perfectly adjusted in a complex measurement process. The gamma values for red (R), green (G) and blue (B) are set for all brightness values from 0 - 255 (8-bit) and 0 - 1023 (10-bit). The diagram shows the target curve and the measurement result of the actual gamma curve. If both curves match, this means that your ColorEdge monitor achieves the ideal gamma curve for accurate greyscale reproduction (grey wedge) without deviating brightness or color nuances.

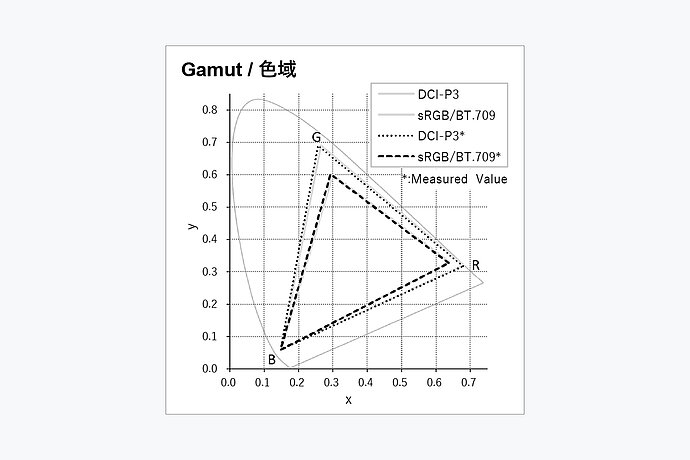

Gamut

There are various norms and standards for color spaces and color gamuts, such as DCI-P3 or AdobeRGB. A monitor's color gamut is often represented as a triangle on the xy color chart created by the CIE (International Commission on Illumination). Most ColorEdge models have a wide color gamut coverage.

The calibration report shows the RGB measurements of the calibrated ColorEdge in comparison to the sRGB/BT.709 and DCI-P3 standards. The color space defined by the standard is shown with a solid line and the monitor's measurement results with a dotted line. This shows how much of each standard color space the ColorEdge monitor covers.

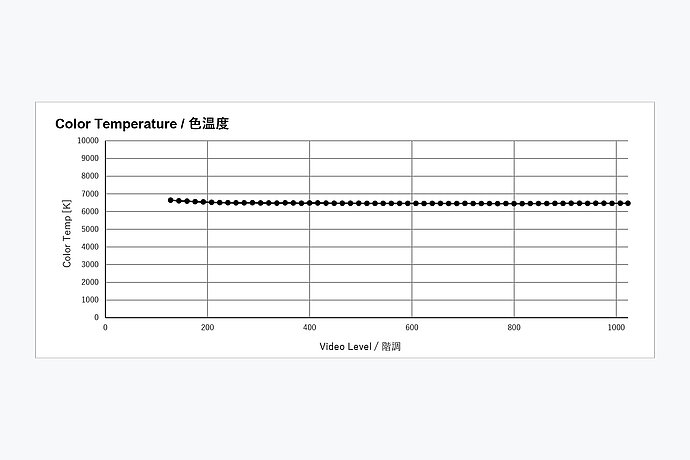

Color temperature

In this diagram, you can see how stable the white point of your monitor remains at different brightness levels. Ideally, the measured values should be as close as possible to the target value of 6500 Kelvin.

The white point of 6500 K is the standard for general PC applications, the sRGB color space and the international standard for digital high definition (ITU-R BT.709).

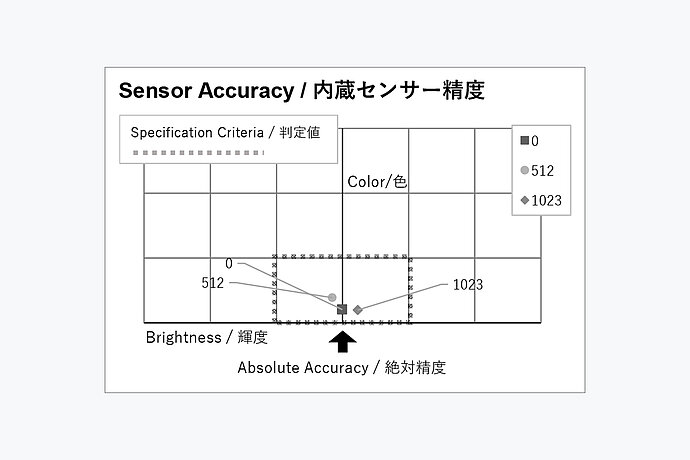

Sensor accuracy

In 2010, EIZO was the first manufacturer in the world to launch a self-calibrating graphics monitor, i.e. a monitor with a built-in sensor. The sensor used in the monitors of the ColorEdge CG series was developed and is also built by EIZO. To ensure excellent measurement accuracy, every sensor integrated in a CG monitor is calibrated with a professional reference-quality spectrophotometer and adjusted together with the built-in panel.

In this way, we ensure that you can absolutely rely on the excellent precision of the measurement sensor installed in your ColorEdge and that you can maintain the precise color and brightness display of the monitor permanently through regular recalibration.

The factory report contains the measurement results of the correlation accuracy between the integrated sensor and the reference spectrophotometer for the brightness values 0, 512 and 1023. The closer the result is to the center of the diagram (marked by the arrow in the illustration below), the higher the absolute accuracy of the integrated calibration sensor. The area marked by the dashed line indicates the strict parameters within which the measurement results must lie for EIZO to classify the values as accurate.

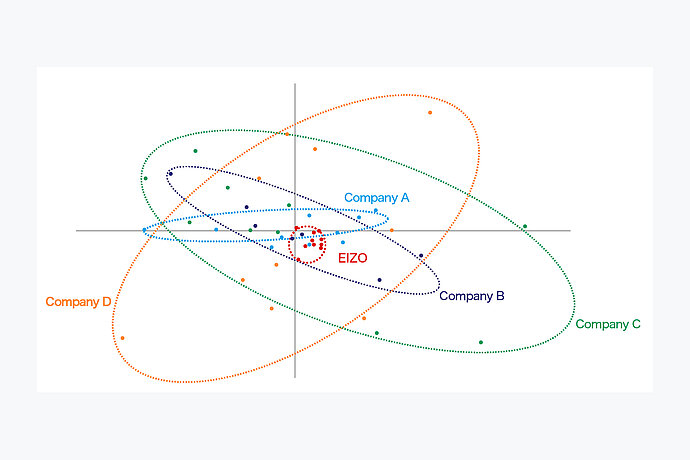

Many external calibration sensors have a relatively large series dispersion. If the monitor is calibrated with such an external measuring device, an inaccurate measurement sensor can lead to an inaccurate calibration.

The following figure shows the typical measurement accuracy of an integrated ColorEdge calibration sensor compared to external calibration sensors from other manufacturers.

Did you already know?

Incidentally, our factory calibration has another advantage: because the monitor has been set so perfectly at the factory, only a few reference points need to be checked during recalibration to compensate for the ageing of the monitor. This is why recalibration with the ColorNavigator is so quick without compromising on precision. In standard mode, all calibration targets are updated with a single recalibration.